With the growing need for computational power and performance, processors are getting bigger—much bigger. Even some of today’s gaming graphics cards push the boundaries of a small package, but they’re relatively small-fry next to AI accelerators and supercomputer chips. From here on out, it’s all about cramming more and more stuff—chiplets, memory, interconnects—onto a single processor. But there are limits to what’s possible.

The limits aren’t just in how much you can stuff into a single silicon chip—that’s a problem that cutting-edge process nodes, chiplets, and interconnects try to solve. There’s also what you put those silicon chips onto afterwards. This is called the substrate, and it’s what allows the silicon chip to communicate with a motherboard. In the case of some chiplet-based processors, the substrate also acts as a way for the chip to communicate to other parts of itself.

For many years, these have been made using organic materials. Before that, ceramic was used. Long before that, in the early days of computing, a lead frame was used. As the need for more computing power grows, so does the need for a substrate that can handle all the connections and density required for bigger, better chips.

At some point in the future, organic substrates might not cut it. One reason why is that chiplet processors require lots of bandwidth to operate effectively, and that means lots of interconnects with lots of individual wires running through a substrate (depending on how they’re hooked together). Another is that lots of chiplets stuffed inside a single package require lots of power and lots of space, and trying to keep these things finely balanced with your performance needs is tricky. At some point, organic substrates may begin to warp or suffer from shrinkage.

Perhaps that’s why this week Intel wanted to share more on what it believes to be the next step: glass substrates.

Glass, Intel believes, is the next step up in substrate tech. In a briefing with Rahul Manepalli, Intel fellow and director of substrate TD module engineering, he explains that glass offers an “order of magnitude improvement in design rules” for future data centre and AI products, citing glass as allowing for more chiplets in a smaller footprint, higher interconnect density, faster IO, higher power efficiency, and larger package sizes. They’re also flatter and more thermally stable.

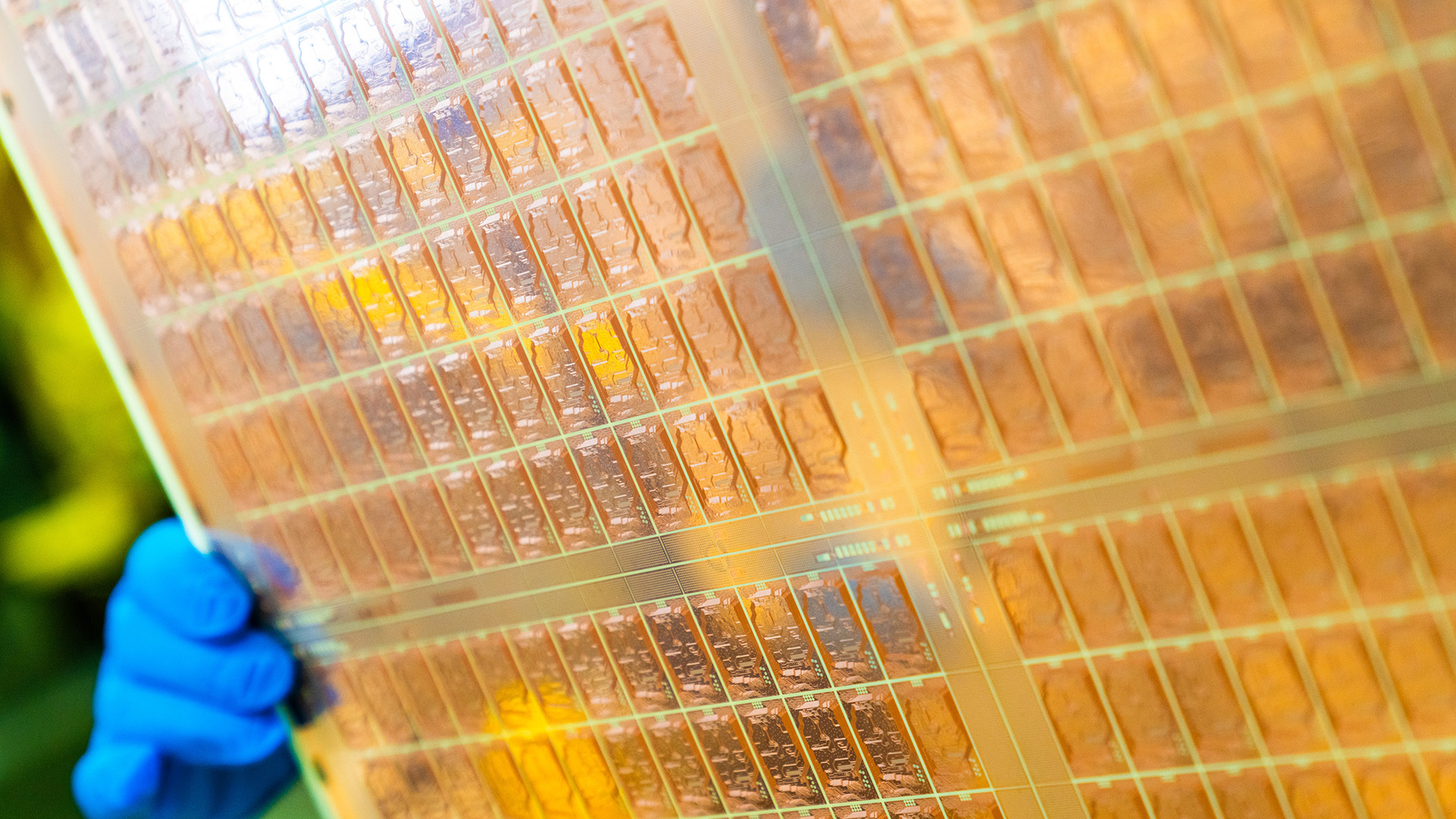

(Image credit: Intel)

Intel says it’s possible to fit 50% more chips on a glass substrate than an organic one of the same size.

Manepalli also notes Intel has been working on glass substrates for a decade already, but that it’ll probably not be until the end of this decade that we see it used in earnest in shipping product. That’ll be starting with massive AI, datacenter and graphics chips that are already bumping up against being too big, but Intel also notes that they do see a benefit to rolling out these substrates to all types of chips one day.

(Image credit: Intel)

(Image credit: Intel)

(Image credit: Future)

Best CPU for gaming: The top chips from Intel and AMD.

Best gaming motherboard: The right boards.

Best graphics card: Your perfect pixel-pusher awaits.

Best SSD for gaming: Get into the game ahead of the rest.

Intel has a glass substrates test chip ready to go, but it’s a long road to mass production. The glass has to meet expectations for its thermal, electrical, and mechanical properties, and it takes a while to tweak the formula to get it right. That’s the thing, the actual formula used to make the glass and the glass’ composition is still in flux, Intel says.

While I was expecting something a little different from the cool see-through images of glass substrates in production from Intel, this test chip is still the tell-tale green we’re used to seeing on a processor. Ah well. This was produced on an Intel test line over in its Chandler facility, where it’s reportedly spending one billion dollars getting its R&D line operational. The line requires all sorts of different technologies to create the new glass substrates, including those from flat panel display manufacturing, Intel’s own EMIB interconnect manufacturing, and organic substrate manufacturing.

Intel isn’t the only company chasing after glass substrate production either, as Dai Nippon Printing has already talked up the benefits of this material for semiconductors. While undoubtedly a long way out, and even longer for gaming CPUs, it seems like there’s a good chance we’ll see this sort of substrate actually make it to market one day.