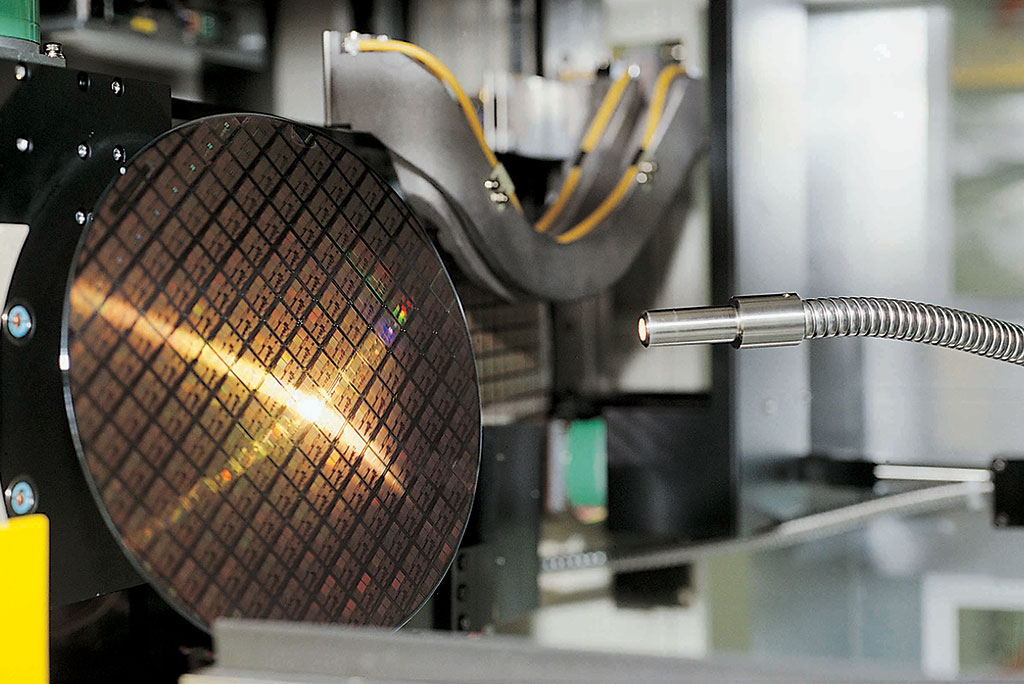

The chips we know and love are made with some of the most advanced manufacturing methods on the planet. The smallest nodes require billions of dollars in capital expenditures, a big part of which goes to Extreme Ultraviolet Lithography machines manufactured by ASML, the current market leader. But there’s a new challenger and some exciting tech on the horizon that aims to change the status quo, potentially leading to a fall in the cost of chips.

Japan-based electronics giant Canon (via Bloomberg) has developed what it calls Nanoimprint Lithography technology that it claims could scale down to 2nm. That’s small enough to rival EUV lithography, but the more important part of this news is the claim that Canon’s technology will have a price of “one digit less than ASML’s EUV tools”. In other words, Canon’s tech should cost just a tenth of an equivalent ASML machine.

ASML is a Netherlands-based company and currently the only supplier of EUV machinery. With that kind of market power, it can pretty much set any price it wants, meaning only the largest companies can afford price tags in the hundreds of millions of dollars to buy ASML’s most advanced EUV tech.

Nanoimprint lithography is pretty much as it sounds. Using NIL, circuits are essentially printed directly onto a wafer. It involves applying a resin directly to the wafer, followed by the pressing of a mold to create surface patterns before ultraviolet light is used to solidify the patterns. However, production yields and the potential for defects remain unanswered questions for now.

Canon CEO Fujio Mitarai was quoted by Bloomberg, saying “I don’t expect nanoimprint technology to overtake EUVs, but I’m confident this will create new opportunities and demand.” Mitarai went on to say “we are already fielding many inquiries from customers.”

The end goal is to enable chip makers to manufacture chips at a lower cost or in smaller batches. To take the glass half-full view, companies will get cheaper chips leading to cheaper products for end users. On the other hand, the glass half-empty view is that chipmakers will just pass savings onto investors as a result of higher margins.

I won’t wade into the business side of things, but it has to be a good thing if smaller fabless companies are able to make advanced chips at a lower cost. Even if we don’t see savings passed onto consumers, it would do the industry no harm to see more competition in the chip making space. Cheaper tools and manufacturing costs should allow more companies to produce chips on nodes that would otherwise be cost prohibitive.

Your next GPU might not be any cheaper, but all of those unheralded chips that go into everything from cars to TVs to automatic pet feeders may well do. Well, that’s the hope anyway.

Good luck Canon. Let’s see where this goes.