If you’ve ever wanted to build your own keyboard then the Ducky ProjectD Outlaw65 is a simple and easy way to go about it. Included in this compact kit are most of the pieces required to build a mechanical keyboard from scratch and a guarantee that every piece will fit together—you need only provide switches and keycaps.

So, why might you want to build your own keyboard when you can pay someone less for one already made? Good question, and if you don’t already get why that might be appealing I don’t have a particularly convincing answer for you. Beyond an opportunity to lube up all your stabilisers and switches before actually putting them inside your keyboard, or the option to customise often inaccessible layers, you mostly need to be in it for the love of the game.

No doubt the concept should appeal to many in the PC gaming community—any excuse to tinker with my setup is gratefully received. And the Ducky Outlaw lets you skip the entire planning process and get right into the keyboard assembly.

Assembly is easy peasy, if you abide by the instructions. Though it still took me around 2.5 hours to complete. Admittedly I was filming the entire process for a TikTok you can catch in the embed below. My camera kept dying, delaying the entire process, and I was working on other parts of my day job at the time. However much I’d like to, I can’t drop absolutely everything to build a keyboard from scratch during work hours. Sigh.

(Image credit: Future)

Size: 65%

Included in kit: Aluminium casing, PCB, choice of top plates, bottom plate, USB Type-C connector, screws and fittings, adjustable feet

Not included in standard kit: Switches, keycaps (First Edition comes with both)

Hot swappable: Yes

Price: £300 (First Edition) | $299

Opening the neat black carry case, I’m greeted by the many bags of components to fit together. There are chunky hunks of metal (I have a silver kit for review), alongside the underlying PCB, sound dampening, and electrical parts. Also a couple packs of screws, washers, and rubber grommets. Pretty much all of which is needed, though Ducky chucks in a bag of spares in case you end up dropping anything.

It would be pretty easy to lose some of these pieces—the screws are especially tiny, but Ducky provides the necessary tools to screw them in: a tiny allen key and a lovely Ducky branded screwdriver.

It’s almost a shame the Ducky screwdriver is so specific to fit the small components included in the build—it would be my go to screwdriver with a couple of key bits. It’s a shame to have to pack it away again at the end of the build.

Before we talk endings, let’s talk beginnings. I started off by building the base for the keyboard, mostly comprised of weighty sandblasted aluminium. First the adjustable feet, then the surround which helps hold in the PCB and other important components. Even though this is a 65% keyboard and lacking plenty of keys you’d usually find on a full-size unit, this is one of the heaviest keyboards I’ve got in my collection.

(Image credit: Future)

(Image credit: Future)

(Image credit: Future)

The Ducky Outlaw weighs in ~1.3kg once completed; a good deal heavier than the larger Asus ROG Strix Scope II 96 at ~1kg.

Once the base is formed, it’s time to move onto the PCB. The first step to preparing the PCB is to lube up the stabilisers included in the case. There are three required for the UK ISO layout I’ve to hand, though the US layout requires another stabiliser for the oversized shift key. Lubing these stabilisers helps improve the final typing experience and makes for a very smooth actuation of the larger keys. Ducky includes some lube and a tiny brush for this purpose in the box, so no need to worry about sorting any of that ahead of time.

You only need a small amount of the included lubricant for the stabilisers themselves, and if you wanted to you could definitely spread it over an entire pack of switches as well. I’ve decided to use NovelKeys Novelias switches for this build, though I’ve not bothered lubing them for this build. They’re an extremely heavy tactile switch I bought back in 2018 and have used sparingly since, and they feel pretty great anyways. No doubt they would be improved with some lube, but I don’t have the best tools for opening each switch.

Once those stabilisers are lubed up, I fit them onto the PCB. This process was made a little tougher due to the instructions being for the US layout and not the UK layout, though I figured it out in the end. Go me.

Next up, the base plate. This is what you might call a tray mount, and there are a couple of options available in the pack to choose from. There’s a black FR4 with gold trim or a white POM option. These feel and sound different to one another, and it requires a bit of experimentation to find out which you prefer. It’s nice to have the option to change this up; finding out which you prefer is going to be handy if you end up getting deep into this whole mechanical keyboard building malarkey. Here’s how Ducky explains the difference between the two:

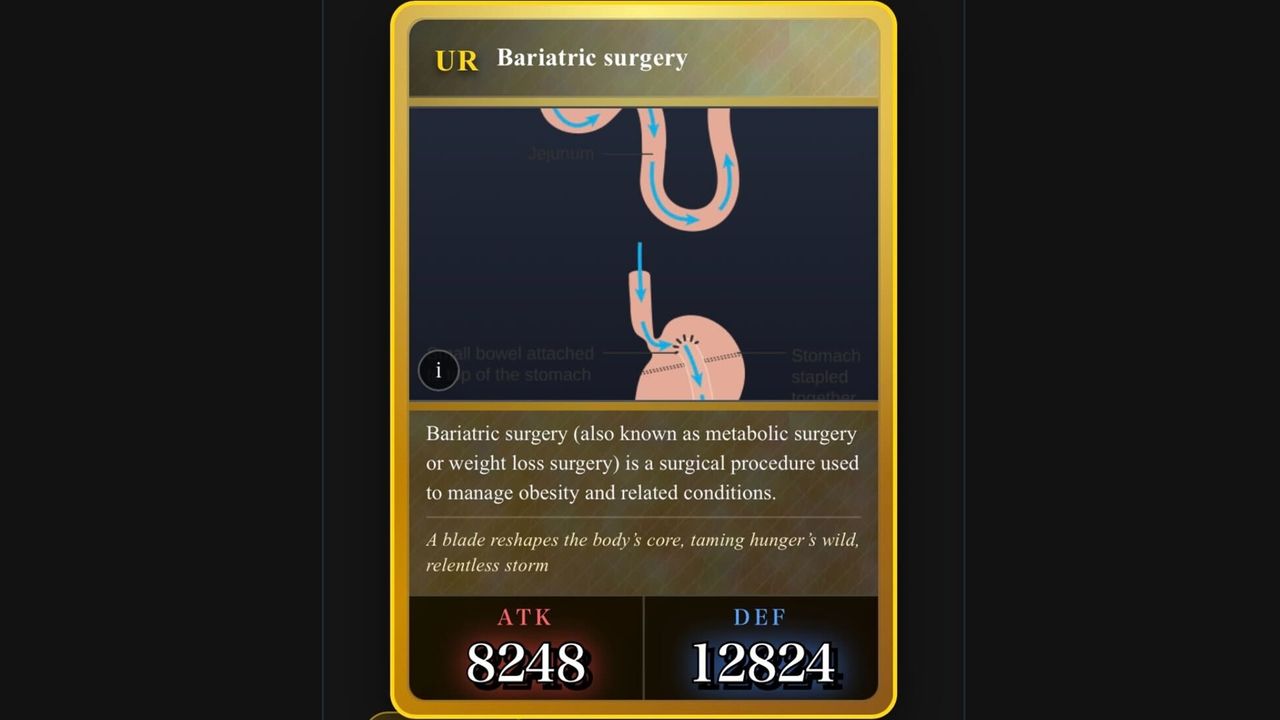

Polyoxymethylene (POM) is an engineering thermoplastic with lithe, low friction, and excellent stability.FR4 glass epoxy is a versatile high-pressure thermoset plastic laminate grade with high stiffness to weight ratios.

I’ve settled on the FR4 for this build, though it’s worth noting the white POM plate will likely help the RGB LEDs included on this keyboard shine a bit brighter behind the caps.

A couple of spacers are required here before slotting the sound dampening foam between it and the PCB and firmly screwing it down. Once that’s sorted, I attached the included USB connector to the PCB and got ready to assemble it all together.

Slot the innards into the outer metal frame, screw everything down, and I’ve pretty much made a mechanical keyboard from scratch.

The next bit, however, is the most repetitive part of the build: switches and caps. Admittedly I quite like the job of plugging in switch after switch into a hot-swappable keyboard—careful not to snap any pins in the process—but it’s not for everyone. The NovelKeys Novelias switches I’ve got at hand for this build fit a gasket mount keyboard such as this, and you’ll need to check compatibility for any others you might use with it. These Novelias also come with a see-through plastic housing on the south side of the switch for RGB LEDs to shine through.

(Image credit: Future)

(Image credit: Future)

(Image credit: Future)

After all the switches are in place, it’s time to do the same all over again with the keycaps.

This keyboard uses, for the most part, traditional UK ISO sized caps, though the left-hand shift key that’s usually 2.75u is replaced by a 1.75u switch. For me that meant stealing some caps off the Wooting 60HE, replacing the caps lock key for the left-hand shift key, and nabbing the caps lock key off a Corsair K65 to replace. It sounds like a janky solution, but it actually looks decent in practice.

(Image credit: Future)

(Image credit: Future)

(Image credit: Future)

(Image credit: Future)

✅ You love the idea of a DIY keeb project: If you naturally find yourself gravitating to projects like this, you’ll have a great time with the Ducky.

✅ You want an all-metal keyboard: This is an expensive board, no doubt, but for a chunky build quality such as this it’s not an unusually high price. You could spend a similar amount on a Varmilo, for example.

❌ You want the cheapest mechanical: It’s probably pretty obvious but you could spend a whole lot less on a mechanical keyboard and still get an impressive keeb.

The only other issue I have that you’ll want to consider if buying a kit for this board is the row of keys down the right-hand side. Del, page up, page down, and end keys are usually spread across two horizontal rows on a normal layout board, yet on this board they’re across four horizontal rows. That means these keys might not stand flush with others in the same row due to the key profile. You can buy completely flat profile keys, such as DSA, or get some other profile keys to match instead. One option would be to replace them with non-specific blank key caps of the correct profile, which I might end up doing.

Speaking of key caps, I had two special Jelly Key artisan keycaps in need of a home and I feel they both look absolutely fantastic on this board. They feature Mario-style worlds and the space bar is translucent so the RGB shines through and something about the silver frame just brings out all the colour in these caps. Yes, I think these will stick around on this board for the foreseeable. It just feels right.

With the whole keyboard finally together at last, I’m able to appreciate the board for what it is. It’s the nicest compact board I’ve personally used in terms of the tactile typing feedback. The rock-solid construction and sheer weight of it see to that. Admittedly the switches I had spare aren’t the most ideal for gaming considering their 90g weight and tactile feedback, but it’s still a mechanical keyboard and still plenty responsive for it.

As a way to build a keyboard from scratch without the planning stage to slow you down, Ducky has delivered a superb kit here. Though it’s not without a custom mech keyboard price tag at £300—thankfully that’s the price for the ‘First Edition’, which does include switches and keycaps. In the US, it will set you back $299 without caps or switches. Nobody said building your own mechanical keyboard was cheap, easy, or necessary—but I’ll be damned if it isn’t incredibly satisfying.